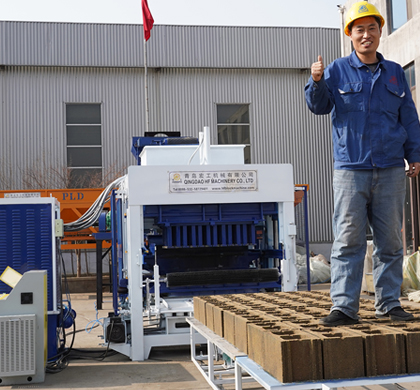

Cement block making machine can produce various types of bricks, such as hollow bricks, permeable bricks, pavement bricks, colored bricks, slope protection bricks, clear water bricks, etc. Generally, bricks of different specifications and models can be produced by changing the mould, and the investment cost is low. A cost-effective brick making equipment.

What are the advantages of Cement block making machine?

What are the basic features of Cement block making machine products?

What is a concrete hollow block machine

1. The processing raw materials used by the Cement block making machine are mostly industrial waste, waste residue, construction waste, etc. There are many types of raw materials, which can realize the reuse of waste materials, which is not only environmentally friendly and energy-saving but also reduces production costs.

2. The mainframe of the Cement block making machine has a reasonable and reliable structure design, good rigidity, high fatigue resistance and long service life.

3. Cement block making machine can produce different types of concrete products such as hollow block,solid block,paving stone and curb stone by changing molds, with high production efficiency, and multi-purpose machine.

4. Cement block making machine adopts a PLC control system, which is easy to operate, reminds of troubleshooting, and is easy to maintain.

5. Cement block making machine adopts high-pressure forming method, with stable technology, high product forming quality, and good consistency.

6. Cement block making machine has a high degree of automation, which can reduce labor intensity, improve work efficiency, and speed up production.

Easy to process. Cement block making machine products have good processing performance. Can saw, planed, nailed, milled, and drilled. And can add reinforcement during the manufacturing process. Concrete blocks bring great convenience and flexibility to construction.

To buy concrete block manufacturing machinery,there are three factors which is recommended to have in your mind:

- Your budget for block making machine

- Your target production capacity for block making plant;

- Quality of the machine, raw materials used to manufacture the block machine, such as the electrical parts,hydraulic components etc..

Block machines play a crucial role in modern construction, facilitating the production of various types of blocks used in buildings, roads, and infrastructure projects. To ensure optimal efficiency and longevity of these machines, it's essential to unders

There are several types of block machines used in various industries for producing different types of blocks, such as concrete blocks, cement blocks, and interlocking blocks. Some common types include:

The first step in maximizing the potential of a brick making machine is to select the right machine for the job. Consider factors such as the size of the bricks you need to produce, the production capacity required, and the specific features and capabilit

Whether for inquiries for inspections and

maintenance, for individual plant optimizations or

extensions, or spare and wear parts.

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.